Safety Equipment

Solder Tools

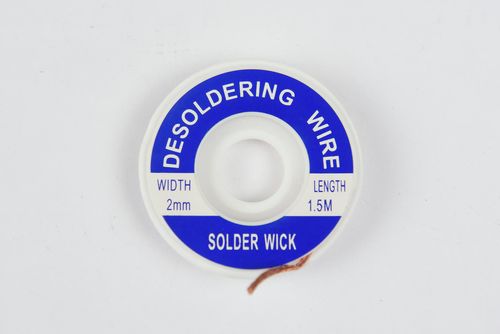

Desoldering Tools

These are the tools that you aren't going to need until you need them, and when you do, you're really going to get your use out of them.

Removing a soldered component is much harder than soldering it in the first place, because, well, let's face it: you're melting two pieces of metal together, then trying to undo that. That's a tall order. So see what's there, and hope you don't have to use these!

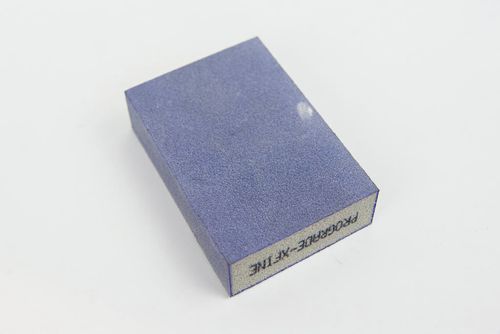

Cleaning Tools

Flux is awesome because it helps the solder stick to the board. Unfortunately, in the process, it leaves a thick nasty residue behind that gets all over your board and eats away at it after awhile. So you want to clean this stuff up as much as is possible.

Normally, you'd dip the entire board in a cleaning solution when the assembly is finished, but that would require lots and lots of solution and is just not that practical. So we're going to clean boards the low-tech way: with paper towels and a little rubbing alcohol!

Other Tools